The jacket filter is a double-layer structure, and the interlayer can be filled with steam or heat transfer oil to maintain or increase the fluid temperature, prevent fluid solidification, improve the filtration speed of viscous liquid, or meet the temperature requirements of the next process

Jacketed filter is mainly composed of connecting pipe, cylinder, filter basket, flange, flange cover and fasteners. Installed on the pipeline can remove large solid impurities in the fluid, so that the machinery and equipment (including compressors, pumps, etc.) and instruments can work and operate normally, so as to stabilize the process and ensure safe production

When the liquid enters the filter basket through the cylinder, the solid impurity particles are blocked in the filter basket, and the clean fluid is discharged from the filter outlet through the filter basket. When cleaning is needed, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reinstall it after cleaning. Therefore, it is very convenient to use and maintain

The filter produced by our company has the advantages of compact structure, large filtering capacity, small pressure loss, wide application range, convenient maintenance and low price. Its main applicable materials are:

1. Weakly corrosive materials in chemical and petrochemical production, such as water, oil products, ammonia, hydrocarbons, etc

2. Corrosive materials in chemical production, such as caustic soda, soda ash, concentrated and dilute sulfuric acid, carbonic acid, aldehyde acid, etc

3. Low temperature materials in refrigeration, such as liquid methane, liquid ammonia, liquid oxygen and various refrigerants

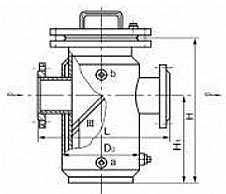

LT GS - Ⅲ jacketed straight through filter

Nominal diameter DN & nbsp | Structure size | Plug specification | ||||||

L | H | H1 | Steam pressure | Ф DO | a | b | W | |

25 | 230 | 350 | 180 |

& le; 1.01Mpa

| 108 | G3/4‘& rsquo; | G3/4‘& rsquo; |

R3/4‘& rsquo; |

32 | 250 | 360 | 180 | 108 | G3/4‘& rsquo; | G3/4‘& rsquo; | ||

40 | 320 | 430 | 210 | 159 | G3/4‘& rsquo; | G3/4‘& rsquo; | ||

50 | 320 | 430 | 210 | 159 | G3/4‘& rsquo; | G3/4‘& rsquo; | ||

65 | 470 | 490 | 250 | 273 | G3/4‘& rsquo; | G3/4‘& rsquo; | ||

80 | 480 | 530 | 290 | 273 | G1‘& rsquo; | G1‘& rsquo; | ||

100 | 520 | 600 | 345 | 325 | G1‘& rsquo; |

Copyright(C)2022,Honghu Lantian Anhuan Energy Saving Equipment Co., Ltd.All Rights Reserved. Supported by Copyright Notice

| ||