The product is mainly used as protective filter for filter separator, flowmeter, control valve, etc. In the occasions with serious particle pollution such as refinery finished product warehouse, transfer oil depot and airport oil depot, it is installed in front of the warehousing filter separator (Class A) (used in series) as a pre filter, which can effectively prolong the service life of coalescence filter element; When installed in front of flowmeter and control valve, it can effectively intercept large particle impurities and prevent mechanical damage

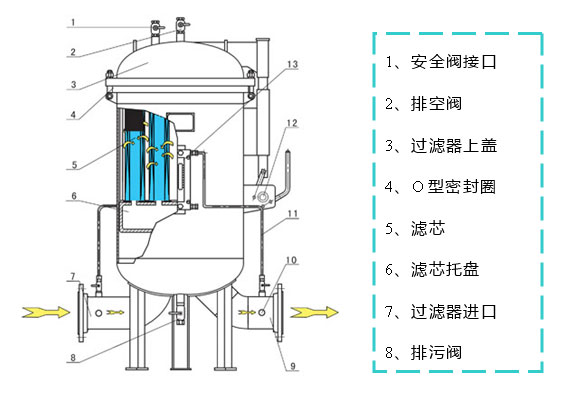

The pre filter is composed of filter element, shell, vent valve, differential pressure gauge, blowdown valve, sampling connector and other accessories. Its basic structure is shown in the figure

The filtered oil enters the lower part of the filter housing from the inlet pipe, and then flows through the filter element from the outside to the inside. At this time, the coarser particles will precipitate immediately (discharged from the sewage outlet) and the smaller particles will be intercepted by the filter element. Finally, the clean oil is collected through the filter element tray and flows out of the filter through the outlet pipe. As the amount of filtered oil increases, the pollutants deposited on the filter element will cause the differential pressure of the filter to rise. When the differential pressure rises to 0.1MPa, it indicates that the filter element has been blocked and should be replaced or cleaned

1) Initial differential pressure: & le; 0.02Mpa

2) Maximum allowable working differential pressure: 0.1MPa

3) Filtering accuracy:

4) Structural strength of filter element: 0.3MPa

|

Filter material |

Ylz-5 filter paper |

Ylz-15 filter paper |

Ylz-30 filter paper |

200 mesh stainless steel mesh |

100 mesh stainless steel mesh |

|

Filtering accuracy |

5μ m |

15μ m |

30μ m |

80μ m |

150μ m |

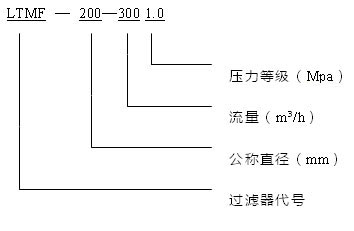

Model designation

According to the difference of rated flow and rated pressure, there are six specifications and twelve models of pre filter

|

Type

|

Appearance dimension (mm)

|

Open nominal diameter

|

Weight(Kg)

|

Volume

L |

||||||

|

A

|

B

|

C

|

D

|

E

|

DN(mm)

|

d1

|

d2

|

|||

|

LTMF100-90/1.0

LTMF100-90/1.6 |

1280

|

1010

|

500

|

250

|

900

|

100

|

Rc1/2

|

Rc3/4

|

210

|

240

|

|

LTMF150-120/1.0

LTMF150-120/1.6 |

1360

|

1180

|

600

|

250

|

1000

|

150

|

Rc1/2

|

Rc3/4

|

320

|

280

|

|

LTMF150-180/1.0

LTMF150-180/1.6 |

1700

|

1280

|

600

|

250

|

1000

|

150

|

Rc1/2

|

Rc3/4

|

360

|

340

|

|

LTMF200-240/1.0

LTMF200-240/1.6 |

1775

|

1376

|

700

|

250

|

1080

|

200

|

Rc1/2

|

Rc3/4

|

480

|

560

|

|

LTMF200-300/1.0

LTMF200-300/1.6 |

1980

|

1490

|

700

|

250

|

1080

|

200

|

Rc1/2

|

Rc3/4

|

510

|

620

|

|

LTMF200-360/1.0

LTMF200-360/1.6 |

1980

|

1690

|

800

|

250

|

1100

|

200

|

Rc1/2

|

Rc3/4

|

510

|

620

|

About Us

Products

News

Case

Technical solutions

Contact Us

Copyright(C)2022,Honghu Lantian Anhuan Energy Saving Equipment Co., Ltd.All Rights Reserved. Supported by Copyright Notice