Ltqs tank automatic dehydrator is a new generation product developed and designed by our company according to the needs of tank dehydration in petrochemical industry. It is made of stainless steel and has the advantages of reasonable design, simple structure, large drainage, fast oil return speed, strong corrosion resistance, convenient, safe and reliable use. This product is used in petroleum and chemical industries, replacing the manual water cutting mode of oil tank, realizing automatic water cutting, greatly reducing the labor intensity of operation and hydrogen sulfide poisoning during manual water cutting, reducing oil waste and environmental pollution, and meeting the specification requirements of concealed channelization and pipelining of petrochemical system discharge

The development and application of automatic dehydrator is undoubtedly an important contribution to the improvement of production technology and production automation in petrochemical industry. It solves the problems that the dehydration of oil tank in petrochemical industry adopts manual operation, the separation of oil and water can not be strictly controlled, the oil content of drainage is relatively high, resulting in waste of oil products and environmental pollution; It overcomes the great potential safety hazard caused by human misoperation. The automatic dehydrator of the storage tank is installed at the lower part of the oil tank. The mechanical force generated by buoyancy is used to automatically open and close the drainage. There is no need for manual intervention, no energy consumption and no explosion-proof problem. It not only ensures the safe operation of production, but also reduces the labor intensity of workers and environmental pollution. The utility model has the advantages of wide application range, convenient installation and use, good safety performance and high reliability

Function: it is installed on the dewatering pipe or blowdown pipe at the lower part of the oil storage tank to automatically open and close the drainage after drainage

Application: it is suitable for automatic oil interception and drainage of oil tanks in oil and petrochemical industries

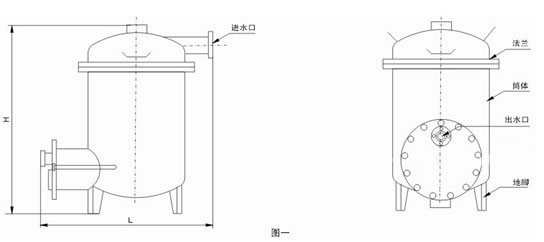

This product is composed of cylinder, inlet and outlet valves and automatic control device (see Figure 1). The buoyancy is generated by the density difference between different oil media and water, and the lever principle is adopted to make the buoy move up and down by relying on the buoyancy difference of the buoy in the oil-water medium. The obtained buoyancy difference is magnified by the high-sensitivity lever system to control the opening and closing of the drain valve, so as to achieve automatic operation. At the same time, the product adopts the special design structure without back pressure to make the opening and closing of the valve more sensitive. It can also realize the automatic monitoring of the system according to the needs of users and automate the dehydration management in the tank farm

The upper part of the dehydrator shell is provided with a water inlet, the lower part is provided with a water outlet, a floating ball is connected with the small valve core at the other end through the connecting rod, and the counterweight is installed on the upper part of the floating ball through the connecting rod. When the floating ball rises or falls under the action of buoyancy, the valve core is driven to open or close the drain through the connecting rod

1. The dehydration principle breaks through the traditional concept of automatic water cutting of oil tank. It perfectly uses Archimedes theorem and lever principle, and realizes automatic dehydration without power supply according to the relationship between oil and water density difference, which is intrinsically safe and reliable

2. It skillfully solves the problem that the residual oil in the dehydrator cannot automatically return to the oil tank in the dehydration process

3. At the end of each dehydration, the water level in the dehydrator is always maintained at a certain height to form an automatic water seal to ensure no oil spillage

4. Complete functions and wide application range

5. There are no wearing parts, long service life and convenient installation and maintenance. There is no need for tank cleaning and hot work during installation

1. Working pressure: & le; 0.6Mpa

2. Operating temperature: & le; 80 ℃ (steam tracing control as required)

3. Nominal water cut: below 10t / h, 12t / h, 15t / h, 20t / h, 30t / h

4. Cut water oil content ≤ 100mg/L

5. Scope of application: suitable for liquid separation of oil products and other chemical products with different specific gravity

Model | H(mm) | L(mm) | Water cut T / h | Inlet pipe diameter | Outlet pipe diameter | Cylinder diameter (mm) | Applicable media |

LTQS-10 | 660 | 724 | & le; 10 | DN80 | DN50 | Ф 500 | For light oil or liquid chemical raw materials |

LTQS-12 | 680 | 724 | 12 | DN80 | DN50 | Ф 500 | Ibid. |

LTQS-15 | 700 | 724 | 15 | DN80 | DN50 | Ф 500 | Ibid. |

LTQS-15A | 700 | 824 | 15 | DN80 | DN50 | Ф 600 | For light oil, liquid chemical raw materials or crude oil |

LTQS-20A | 720 | 824 | 20 | DN100 | DN50 | Ф 600 | For crude oil, residue and wax oil |

LTQS-30A | 720 | 824 | 30 | DN100 | DN50 | Ф 600 | Ibid. |

1. This product is required to be installed on a stable and solid foundation. The water inlet shall be flat or slightly lower than the oil tank drain

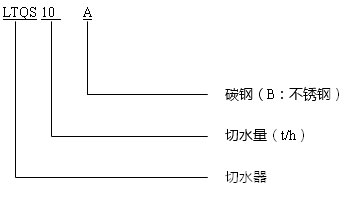

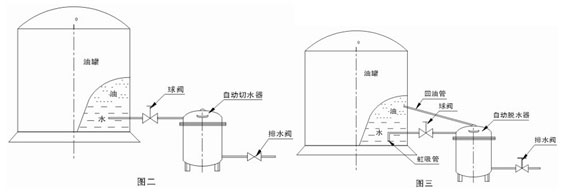

2. There are two installation methods: ① installation of oil tank without siphon (see Figure 2). ② Installation of oil tank with siphon (see Figure 3)

3. All fasteners in the pipeline shall be tightened, and the connection point shall be sealed, and liquid leakage is not allowed. The water cut-off shall be debugged and fixed by matching the counterweight code of corresponding model according to the oil type of the user

4. The valves connecting the oil tank and the dehydrator shall be straight through valves such as gate valves and straight pipes without elbows, otherwise the oil return will be affected

5. Steam heat tracing pipe shall be installed in northern areas to prevent freezing. The connecting valve between the dehydrator with steam heat tracing pipe and the oil tank shall not be closed to prevent overtemperature and pressurization

Precautions

1. The valve at the outlet of the oil tank shall be of straight through type (such as single valve, ball valve, etc.)

2. The pipeline from the oil tank to the dehydrator shall be horizontal or slope to the dehydrator

3. The oil tank outlet pipe is equipped with elbow (siphon type). It is recommended to cancel the elbow. If the elbow cannot be cancelled, an oil return pipe must be set, with a diameter of DN32

4. & ldquo; should be set for the dehydration of Dacron in cold areas or viscous oil products; Self supporting temperature control valve & rdquo

5. It is recommended to add heat tracing and insulation to the dehydration pipeline and oil return line of oil tank in cold areas

6. For oil tanks with large volume or oil products with high moisture content or short dehydration cycle, it is recommended to appropriately increase the number of dehydrators

7. Regularly remove the sediment in the dehydrator and filter to ensure the normal operation of the dehydrator

8. Regularly check whether the dehydrator leaks oil, and timely replace the sealing ring of the double valve

9. Pay attention to exhaust during the operation of the dehydrator to avoid gas resistance affecting the normal operation of the dehydrator

10. It is normal that the dehydrator cannot dehydrate normally in case of emulsified oil sludge layer, and a manual water cut-off shall be set in front of the dehydrator

About Us

Products

News

Case

Technical solutions

Contact Us

Copyright(C)2022,Honghu Lantian Anhuan Energy Saving Equipment Co., Ltd.All Rights Reserved. Supported by Copyright Notice