Lthq oil mixer is a special equipment for petrochemical liquid blending jointly developed by our company and Baling Petrochemical Design Institute

It is installed at the top, middle, side walls and bottom of the tank. (as shown below)

.jpg)

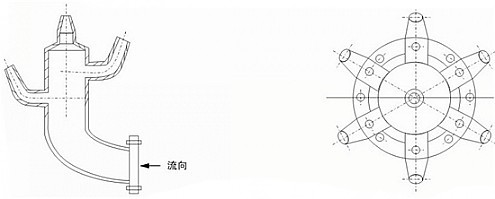

Lthq oil product mixer is connected with the liquid inlet pipeline through the equipment flange. The side wall and top of the mixer shell are equipped with liquid nozzles. During feeding, the liquid is ejected from the nozzles evenly distributed around, which can fully mix the materials into the tank with the original materials in the tank without separate operation. So as to achieve the purpose of heat transfer homogenization, shorten the mixing time, save energy and reduce consumption, reduce evaporation loss and so on. It has the advantages of compact structure, convenient operation, safety and reliability, high efficiency and avoiding oil oxidation. The product series is divided into single nozzle and multi nozzle. The single nozzle is a streamlined cone. Multiple nozzles are divided into 5 and 7 nozzle combinations. Multiple nozzles have the advantages of shortening cycle time, saving energy and reducing consumption, reducing evaporation loss and so on. A sketch is attached

Lthq mixer determines the inclination angle of its lateral nozzle and the size of nozzle aperture according to the size of storage tank, liquid viscosity, installation position, pump head and many other factors

The nominal pressure of lthq oil product mixer produced by our company is generally 1.6Mpa, and the nominal diameters are DN100, DN150, DN200, DN250 and DN300. The material is determined according to the materials stored in the user's storage tank

Lthq oil blending device solves the problems that cannot be solved by the mixer. It is especially suitable for the blending of medium and high-grade materials with certain requirements for blending proportion, large scale change range, large batch and no blending dead corner. It has high efficiency, convenient management and no blending dead corner

Oil blending device | oil blending device | nozzle | liquid blending device | oil blending in tank

About Us

Products

News

Case

Technical solutions

Contact Us

Copyright(C)2022,Honghu Lantian Anhuan Energy Saving Equipment Co., Ltd.All Rights Reserved. Supported by Copyright Notice